• This software provides design, sensitivity analysis, and cost estimation of multicomponent distillation columns.

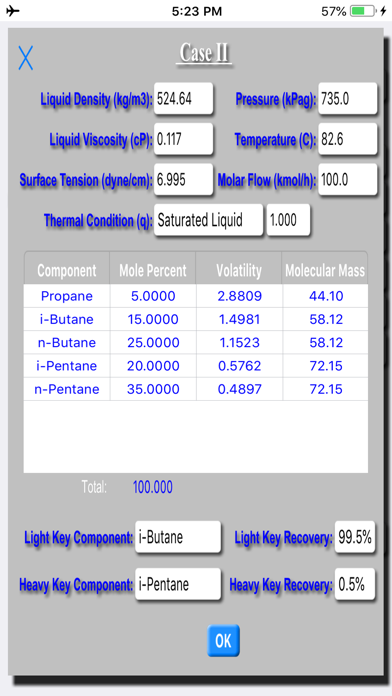

• Define your own system of multicomponent (2-40 component) distillation and see the products and economic evaluations.

• The most reliable equations and correlations are being used here for design calculations.

• The models involved in the design phase are Fenske, Underwood, Erbar-Maddox, OConnell, Kirkbride, and Fair.

• The vapor-Liquid disengagement area at top and a liquid residence time of 5 min at bottom are considered while calculating the height of column.

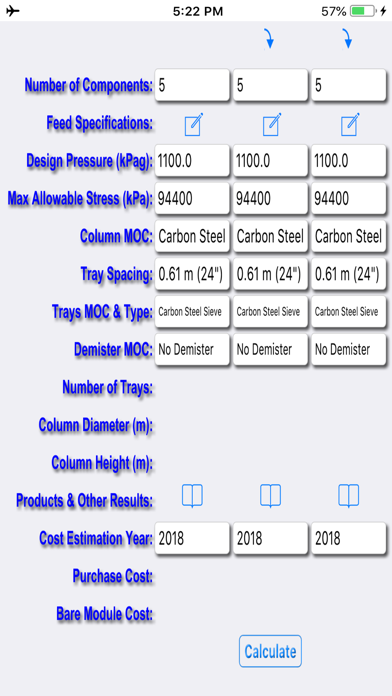

• The Purchased Cost and the Bare Module Cost are estimated for years ranged from 1957 to present.

• All affecting economic parameters, i.e. size, pressure, temperature, materials of construction, and inflation are taken into account.

• Thanks to incorporating average values of published cost data, the estimation accuracy is at a high level of ±12%.

• The cost estimation method is adopted from Turton et al. (2018) who reviewed and updated the modular technique and cost data proposed by Guthrie (1974) and Ulrich (1984).

References:

- Guthrie, K.M., "Process Plant Estimating, Evaluation and Control", Solana Beach, 1974.

- Turton, R., Shaeiwitz, J.A., Bhattacharyya, D., Whiting, W.B., "Analysis, Synthesis, and Design of Chemical Processes", Fifth Edition, Pearson Education, 2018.

- Ulrich, G.D., "A Guide to Chemical Engineering Process Design and Economics", John Wiley and Sons, 1984.